High-Efficiency Dirty Turbine Oil Recondition and Purification Machine

Features1. Adopt coalescence and separation technique, 3D-Evaporation technical and thin film evaporation technique. Strong ability to break the emulsion and remove water from the oil.

2. Optimized electric heating system with automatic constant temperature controller ensures even and stable oil temperature, and can protect the oil from over-heating and dry-heating.

3. Precise multi-stage filtration system helps remove different kinds of impurities with a high-quality filter element with a better ability to contain pollutants and long service life.

4. Advanced oil level control system and pressure protection device make operation simple and safe.

5. Can purify any kinds of turbine oil used in steam turbines and water turbines online and onsite.

6. Advanced automatic protection & alarm system, if the machine overpressure or overloads, or oil flows into the cooler, the machine will alarm and stop working automatically, making the equipment operate safely and avoiding damage to components.

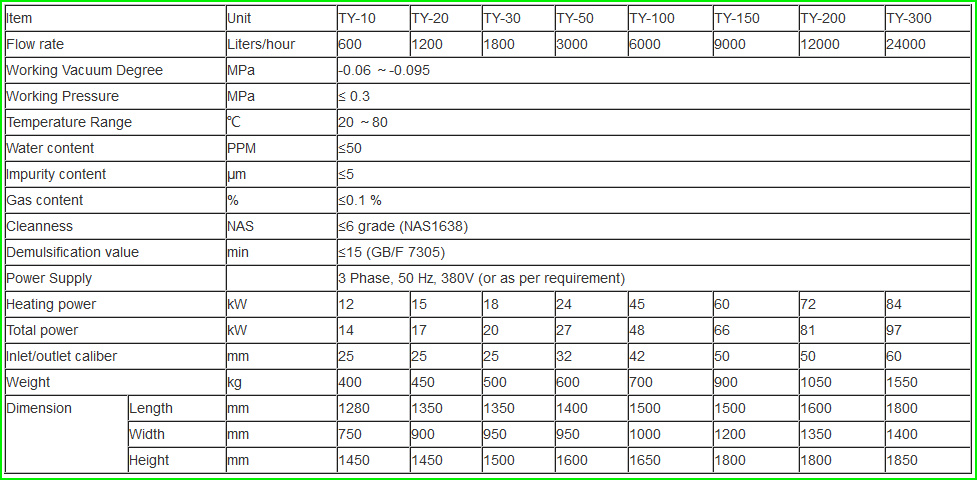

Technical Parameters