High Efficiency Insulating Oil Filtration and Purification Machine

Application REXON ZY-30(1800litres/hour) high efficiency insulating oil filtration and purification machine is applied for purifying aging transformer oil, mutual inductor oil, switch oil, capacitor oil in fields of power transmission and transformation equipment, electric power department and mining enterprises. It can thoroughly degas, dehydrate, and filter the oil to quickly restore the dielectric strength.

Features1. This type machine is skid mounted and easy to move. It can also be installed in a small truck or van for different onsite project use.

2. Strong impurity removal ability, high β value precision filter material, multi-stage filtration is gradually encrypted to remove fine particles in the oil. The filter element has a large volume and a large dirt-holding capacity.

3. This machine is highly efficient with stereo multistage vacuum system whose efficiency is higher than that of ordinary vacuum oil purifier by 3-5 times. It is able to remove the water, gases and other mechanical impurities out of the insulating oil, and improve the voltage withstanding strength and oil quality, making sure the power equipment works safely.

4. The system adopts low-density indirect circulation carbon fiber heating technology to prevent oil cracking and produce acetylene gas. Low energy consumption, uniform heating and stable oil temperature.

5. Automatic control: this system adopts high-end sophisticated configurations such as automatic constant temperature control, automatic liquid level control, automatic defoaming control, automatic pressure protection, etc., to ensure that the equipment does not spray oil during operation, and runs safely and stably.

6. Interlock protection: Overload protection, overpressure alarm shutdown protection, oil shortage protection, fuel injection protection, phase sequence protection, etc. ensure the long-term reliable operation of the whole machine.

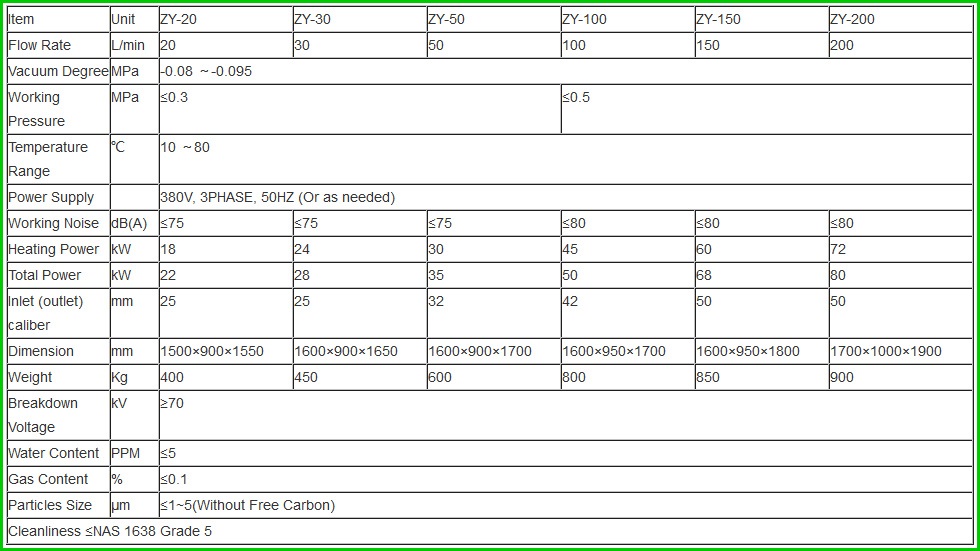

7. Humanized instructions: automatic design, and there are instructions for oil temperature, pressure, vacuum degree, filter element pollution degree, operation status, etc., and the labels are concise and clear.Technical Parameters